Июн . 27, 2024 14:30

Back to list

Efficiently Remove Brad Nails from Trim in Manufacturing Settings

The Importance of Removing Brad Nails from Trim Factories A Sustainable Manufacturing Perspective

In the realm of woodworking and construction, trim factories play a crucial role in crafting intricate details and finishing touches for various structures. However, one aspect that often goes unnoticed but is of significant importance is the safe and efficient removal of brad nails from these factories. This process not only ensures the quality of the final product but also contributes to a safer working environment and sustainable manufacturing practices.

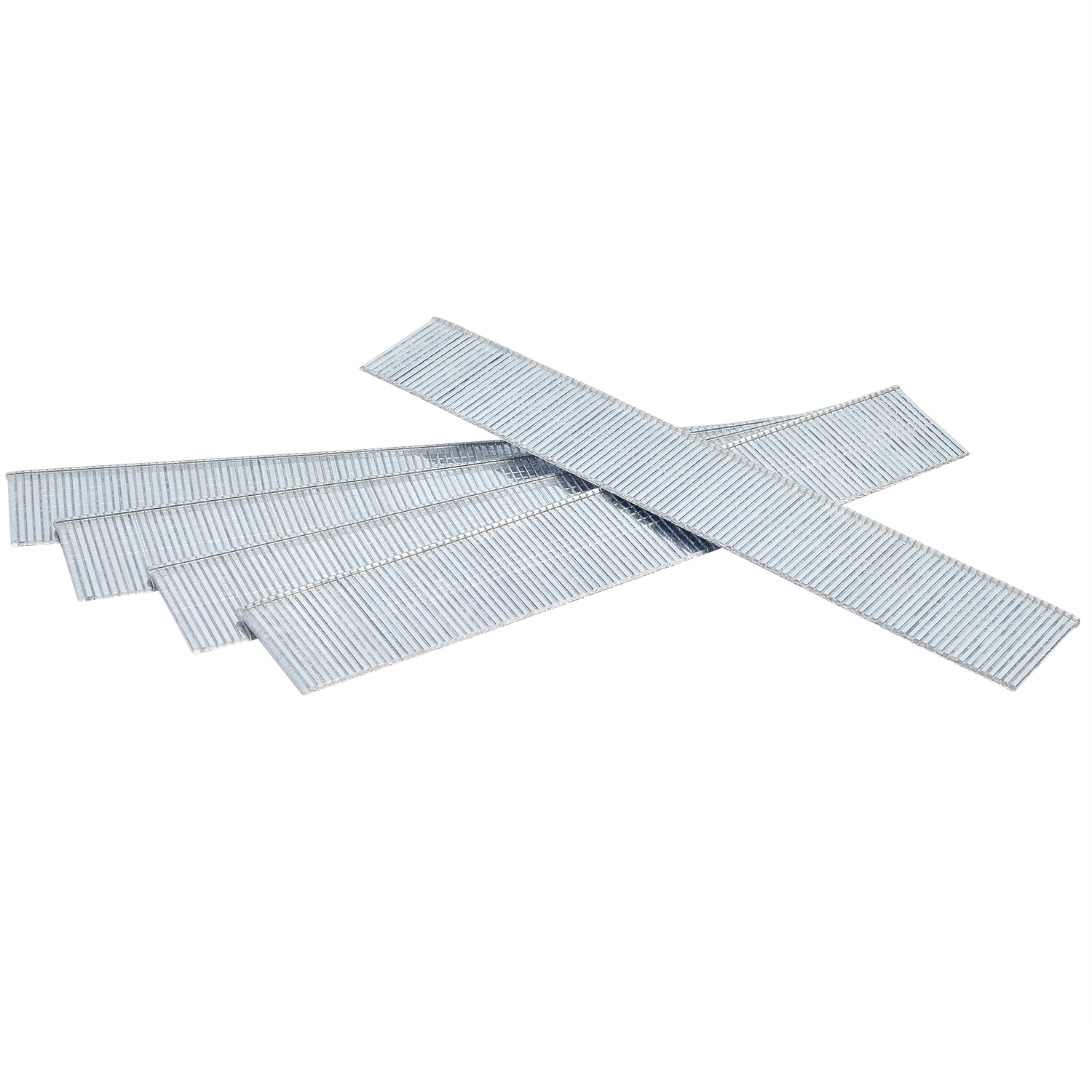

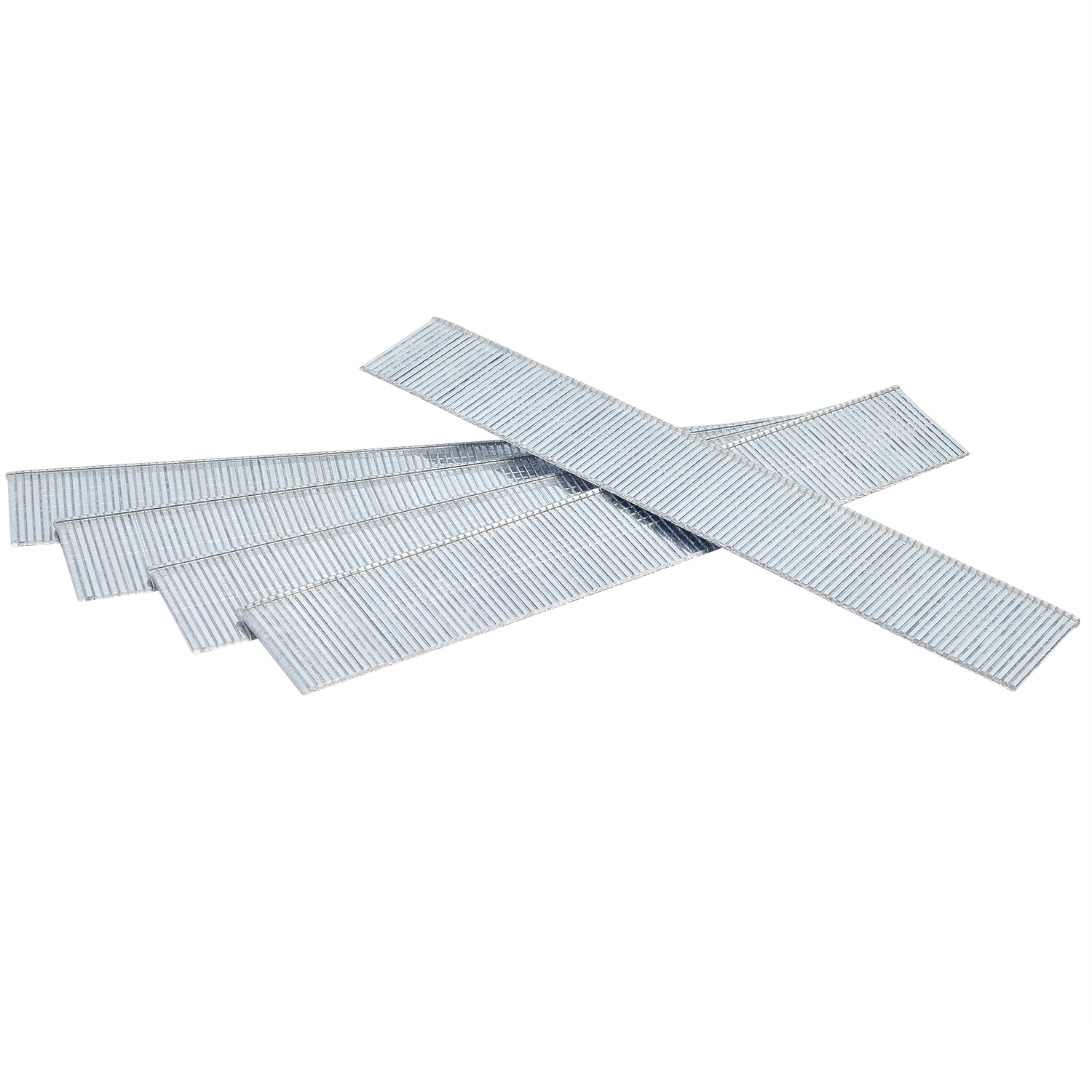

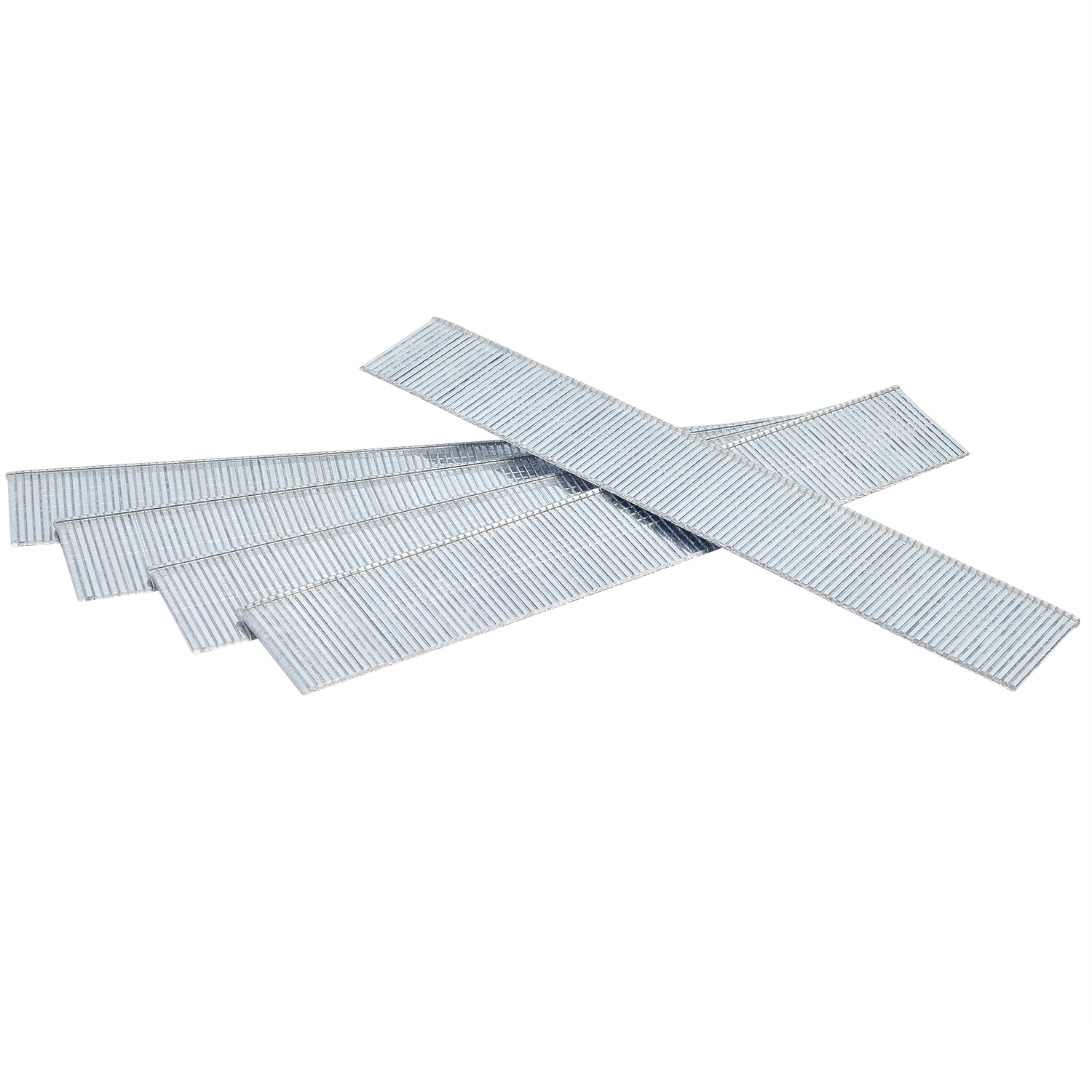

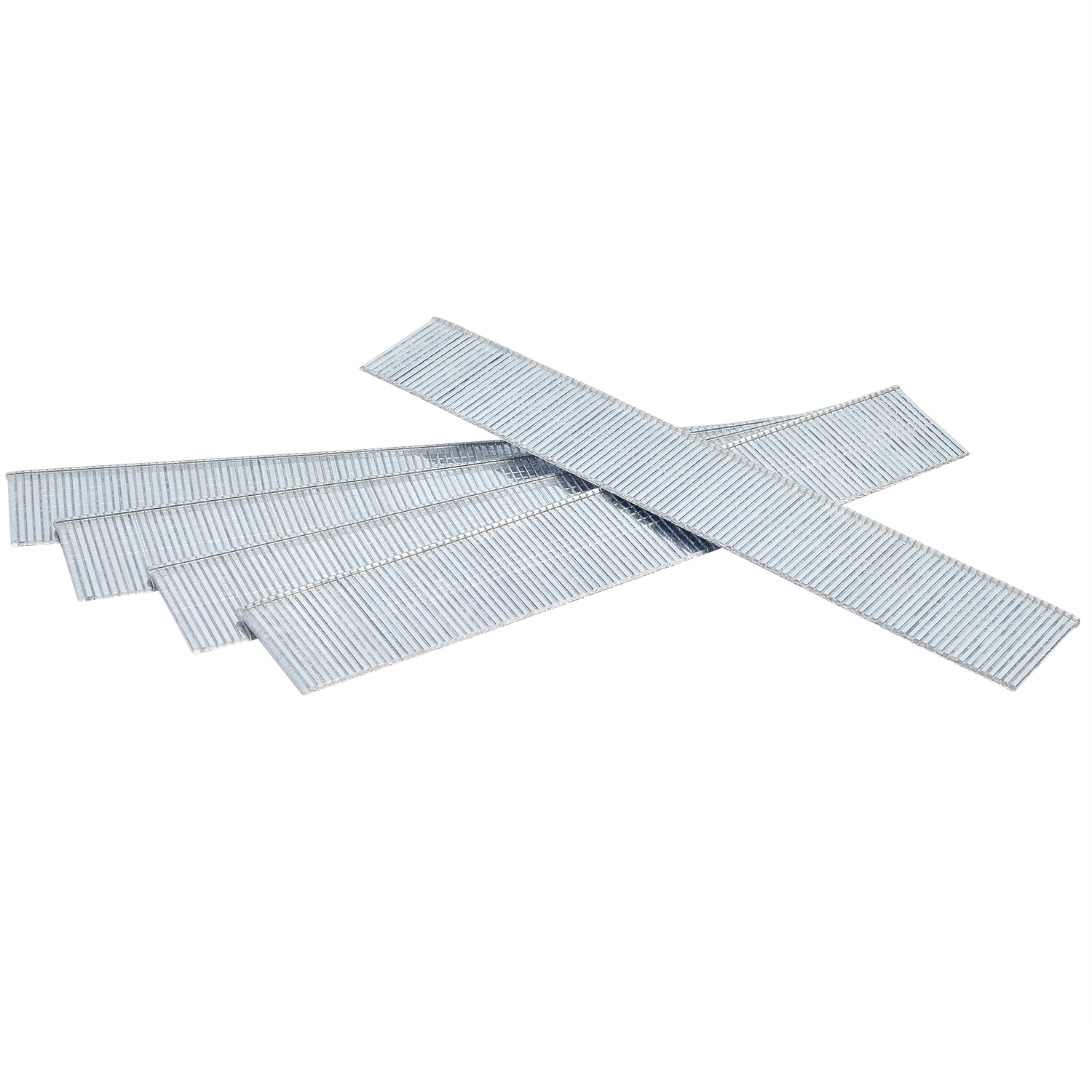

Brad nails, with their slender design and small heads, are commonly used in trim work due to their ability to hold materials securely without causing substantial damage. Despite their utility, the presence of unused or protruding brad nails can pose hazards to both workers and machinery in the factory setting. Sharp edges can lead to accidental injuries, while nails left in the wood can cause damage during transportation or installation.

The removal of brad nails from trim factories should be a standard procedure, carried out meticulously by skilled technicians using specialized tools such as pliers or nail pullers. This step not only safeguards the well-being of employees but also prevents potential damage to the finished trim pieces, maintaining the integrity and aesthetic appeal of the product.

Moreover, the disposal of removed brad nails must adhere to eco-friendly principles. Recycling programs can be implemented to collect and repurpose these nails, reducing waste and conserving resources Recycling programs can be implemented to collect and repurpose these nails, reducing waste and conserving resources Recycling programs can be implemented to collect and repurpose these nails, reducing waste and conserving resources Recycling programs can be implemented to collect and repurpose these nails, reducing waste and conserving resources

Recycling programs can be implemented to collect and repurpose these nails, reducing waste and conserving resources Recycling programs can be implemented to collect and repurpose these nails, reducing waste and conserving resources remove brad nails from trim factories. By doing so, trim factories contribute to a circular economy, where waste is minimized, and materials are reused or recycled.

In addition to safety and sustainability, removing brad nails from trim factories can also enhance operational efficiency. Clearing workstations of unnecessary debris promotes a cleaner and more organized workspace, leading to increased productivity and reduced downtime. Furthermore, it ensures that machinery operates smoothly, preventing potential jams or malfunctions caused by stray nails.

In conclusion, the removal of brad nails from trim factories is a critical aspect of responsible manufacturing. It is a practice that combines worker safety, product quality, and environmental consciousness. As the industry continues to evolve, prioritizing this process will not only minimize risks but also contribute to a more sustainable future for woodworking and construction. By embracing this approach, trim factories can set a benchmark for responsible manufacturing, fostering a culture of care, efficiency, and environmental stewardship.

remove brad nails from trim factories. By doing so, trim factories contribute to a circular economy, where waste is minimized, and materials are reused or recycled.

In addition to safety and sustainability, removing brad nails from trim factories can also enhance operational efficiency. Clearing workstations of unnecessary debris promotes a cleaner and more organized workspace, leading to increased productivity and reduced downtime. Furthermore, it ensures that machinery operates smoothly, preventing potential jams or malfunctions caused by stray nails.

In conclusion, the removal of brad nails from trim factories is a critical aspect of responsible manufacturing. It is a practice that combines worker safety, product quality, and environmental consciousness. As the industry continues to evolve, prioritizing this process will not only minimize risks but also contribute to a more sustainable future for woodworking and construction. By embracing this approach, trim factories can set a benchmark for responsible manufacturing, fostering a culture of care, efficiency, and environmental stewardship.

Recycling programs can be implemented to collect and repurpose these nails, reducing waste and conserving resources Recycling programs can be implemented to collect and repurpose these nails, reducing waste and conserving resources

Recycling programs can be implemented to collect and repurpose these nails, reducing waste and conserving resources Recycling programs can be implemented to collect and repurpose these nails, reducing waste and conserving resources remove brad nails from trim factories. By doing so, trim factories contribute to a circular economy, where waste is minimized, and materials are reused or recycled.

In addition to safety and sustainability, removing brad nails from trim factories can also enhance operational efficiency. Clearing workstations of unnecessary debris promotes a cleaner and more organized workspace, leading to increased productivity and reduced downtime. Furthermore, it ensures that machinery operates smoothly, preventing potential jams or malfunctions caused by stray nails.

In conclusion, the removal of brad nails from trim factories is a critical aspect of responsible manufacturing. It is a practice that combines worker safety, product quality, and environmental consciousness. As the industry continues to evolve, prioritizing this process will not only minimize risks but also contribute to a more sustainable future for woodworking and construction. By embracing this approach, trim factories can set a benchmark for responsible manufacturing, fostering a culture of care, efficiency, and environmental stewardship.

remove brad nails from trim factories. By doing so, trim factories contribute to a circular economy, where waste is minimized, and materials are reused or recycled.

In addition to safety and sustainability, removing brad nails from trim factories can also enhance operational efficiency. Clearing workstations of unnecessary debris promotes a cleaner and more organized workspace, leading to increased productivity and reduced downtime. Furthermore, it ensures that machinery operates smoothly, preventing potential jams or malfunctions caused by stray nails.

In conclusion, the removal of brad nails from trim factories is a critical aspect of responsible manufacturing. It is a practice that combines worker safety, product quality, and environmental consciousness. As the industry continues to evolve, prioritizing this process will not only minimize risks but also contribute to a more sustainable future for woodworking and construction. By embracing this approach, trim factories can set a benchmark for responsible manufacturing, fostering a culture of care, efficiency, and environmental stewardship. Latest news

-

Manufacturer producing brad nails for staple guns with high quality and durability.NewsJul.16,2024

-

CE certification for 5-8mm brad nails and its importance in construction.NewsJul.16,2024

-

Top 16 Gauge Brad Nail Manufacturers with High Quality Products and ServicesNewsJul.16,2024

-

China 18 Gauge Brad Nails for Precision Carpentry Projects in 2021.NewsJul.16,2024

-

Top manufacturer of BN1810 brad nails, providing high quality products for various applications.NewsJul.16,2024

-

Get the job done with 18-gauge staples in 40mm size for various projects.NewsJul.15,2024