Jun . 17, 2024 16:59

Back to list

Producers of 1.25 brad nails

The Pivotal Role of 1.25 Brad Nails in Manufacturing Industries

In the realm of manufacturing, precision and efficiency are paramount. One tool that has significantly contributed to these standards is the 1.25 brad nail, a staple in various woodworking and construction applications. These small yet mighty fasteners have revolutionized the way we think about assembly and construction, offering a blend of strength, subtlety, and convenience.

Brad nails, named for their thin and slender design, are typically used where a smaller, less visible nail is required. The 1.25-inch variant is a popular choice due to its optimal length for medium-duty tasks. They are ideal for attaching trim, molding, or other delicate materials without splitting or damaging the wood surface. Their small heads allow for a near-invisible finish, ensuring an aesthetically pleasing outcome.

Manufacturers of 1.25 brad nails employ advanced technology and high-quality materials to ensure consistency and durability. The nails are usually made from steel, with some incorporating galvanization for added rust resistance. The manufacturing process involves cutting, forming, and polishing, followed by strict quality control checks to guarantee precision and reliability The manufacturing process involves cutting, forming, and polishing, followed by strict quality control checks to guarantee precision and reliability The manufacturing process involves cutting, forming, and polishing, followed by strict quality control checks to guarantee precision and reliability The manufacturing process involves cutting, forming, and polishing, followed by strict quality control checks to guarantee precision and reliability

The manufacturing process involves cutting, forming, and polishing, followed by strict quality control checks to guarantee precision and reliability The manufacturing process involves cutting, forming, and polishing, followed by strict quality control checks to guarantee precision and reliability 1.25 brad nails manufacturers.

The production of these nails often involves automated machinery that can produce thousands of nails per minute with remarkable accuracy. The use of robotics and computer-controlled systems not only enhances speed but also reduces human error, resulting in a more efficient and consistent product.

Moreover, 1.25 brad nails manufacturers cater to a diverse range of industries, from furniture making to home renovation. They collaborate closely with power tool manufacturers to develop nails compatible with specific nail guns, ensuring seamless integration into the workflow of professionals and DIY enthusiasts alike.

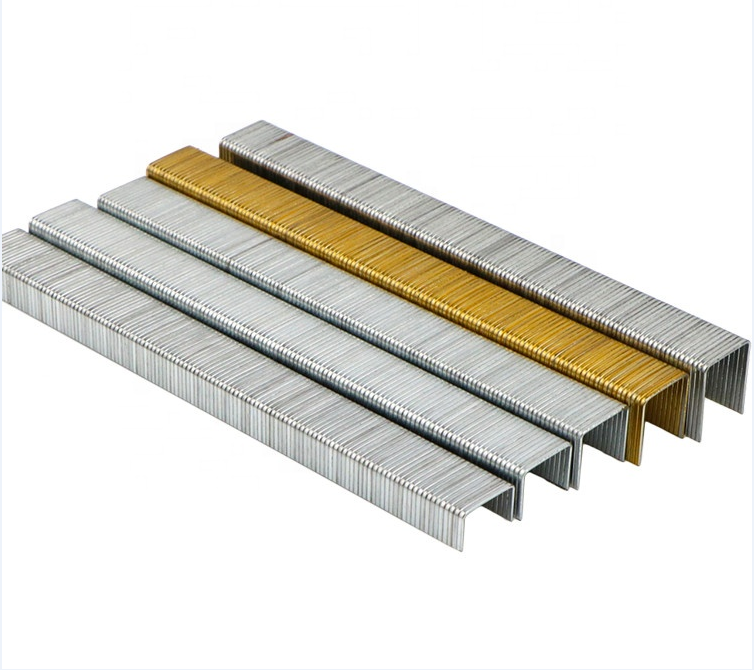

The advent of specialized packaging, such as collated strips or coils, has further streamlined the use of 1.25 brad nails. This design allows for quick and easy loading into nail guns, minimizing downtime and boosting productivity on job sites.

In conclusion, the 1.25 brad nails manufacturers play a crucial role in modern manufacturing. Their commitment to precision engineering, material quality, and user-centric design has solidified the position of these nails as indispensable tools in woodworking and construction. As technology continues to evolve, it's exciting to anticipate how these manufacturers will innovate and refine their products to meet the ever-changing needs of the industry.

1.25 brad nails manufacturers.

The production of these nails often involves automated machinery that can produce thousands of nails per minute with remarkable accuracy. The use of robotics and computer-controlled systems not only enhances speed but also reduces human error, resulting in a more efficient and consistent product.

Moreover, 1.25 brad nails manufacturers cater to a diverse range of industries, from furniture making to home renovation. They collaborate closely with power tool manufacturers to develop nails compatible with specific nail guns, ensuring seamless integration into the workflow of professionals and DIY enthusiasts alike.

The advent of specialized packaging, such as collated strips or coils, has further streamlined the use of 1.25 brad nails. This design allows for quick and easy loading into nail guns, minimizing downtime and boosting productivity on job sites.

In conclusion, the 1.25 brad nails manufacturers play a crucial role in modern manufacturing. Their commitment to precision engineering, material quality, and user-centric design has solidified the position of these nails as indispensable tools in woodworking and construction. As technology continues to evolve, it's exciting to anticipate how these manufacturers will innovate and refine their products to meet the ever-changing needs of the industry.

The manufacturing process involves cutting, forming, and polishing, followed by strict quality control checks to guarantee precision and reliability The manufacturing process involves cutting, forming, and polishing, followed by strict quality control checks to guarantee precision and reliability

The manufacturing process involves cutting, forming, and polishing, followed by strict quality control checks to guarantee precision and reliability The manufacturing process involves cutting, forming, and polishing, followed by strict quality control checks to guarantee precision and reliability 1.25 brad nails manufacturers.

The production of these nails often involves automated machinery that can produce thousands of nails per minute with remarkable accuracy. The use of robotics and computer-controlled systems not only enhances speed but also reduces human error, resulting in a more efficient and consistent product.

Moreover, 1.25 brad nails manufacturers cater to a diverse range of industries, from furniture making to home renovation. They collaborate closely with power tool manufacturers to develop nails compatible with specific nail guns, ensuring seamless integration into the workflow of professionals and DIY enthusiasts alike.

The advent of specialized packaging, such as collated strips or coils, has further streamlined the use of 1.25 brad nails. This design allows for quick and easy loading into nail guns, minimizing downtime and boosting productivity on job sites.

In conclusion, the 1.25 brad nails manufacturers play a crucial role in modern manufacturing. Their commitment to precision engineering, material quality, and user-centric design has solidified the position of these nails as indispensable tools in woodworking and construction. As technology continues to evolve, it's exciting to anticipate how these manufacturers will innovate and refine their products to meet the ever-changing needs of the industry.

1.25 brad nails manufacturers.

The production of these nails often involves automated machinery that can produce thousands of nails per minute with remarkable accuracy. The use of robotics and computer-controlled systems not only enhances speed but also reduces human error, resulting in a more efficient and consistent product.

Moreover, 1.25 brad nails manufacturers cater to a diverse range of industries, from furniture making to home renovation. They collaborate closely with power tool manufacturers to develop nails compatible with specific nail guns, ensuring seamless integration into the workflow of professionals and DIY enthusiasts alike.

The advent of specialized packaging, such as collated strips or coils, has further streamlined the use of 1.25 brad nails. This design allows for quick and easy loading into nail guns, minimizing downtime and boosting productivity on job sites.

In conclusion, the 1.25 brad nails manufacturers play a crucial role in modern manufacturing. Their commitment to precision engineering, material quality, and user-centric design has solidified the position of these nails as indispensable tools in woodworking and construction. As technology continues to evolve, it's exciting to anticipate how these manufacturers will innovate and refine their products to meet the ever-changing needs of the industry. Latest news

-

Manufacturer producing brad nails for staple guns with high quality and durability.NewsJul.16,2024

-

CE certification for 5-8mm brad nails and its importance in construction.NewsJul.16,2024

-

Top 16 Gauge Brad Nail Manufacturers with High Quality Products and ServicesNewsJul.16,2024

-

China 18 Gauge Brad Nails for Precision Carpentry Projects in 2021.NewsJul.16,2024

-

Top manufacturer of BN1810 brad nails, providing high quality products for various applications.NewsJul.16,2024

-

Get the job done with 18-gauge staples in 40mm size for various projects.NewsJul.15,2024