Jun . 22, 2024 04:35

Back to list

Galvanized Brad Nails Manufacturer Overview

Galvanized Brad Nails A Manufacturer's Perspective

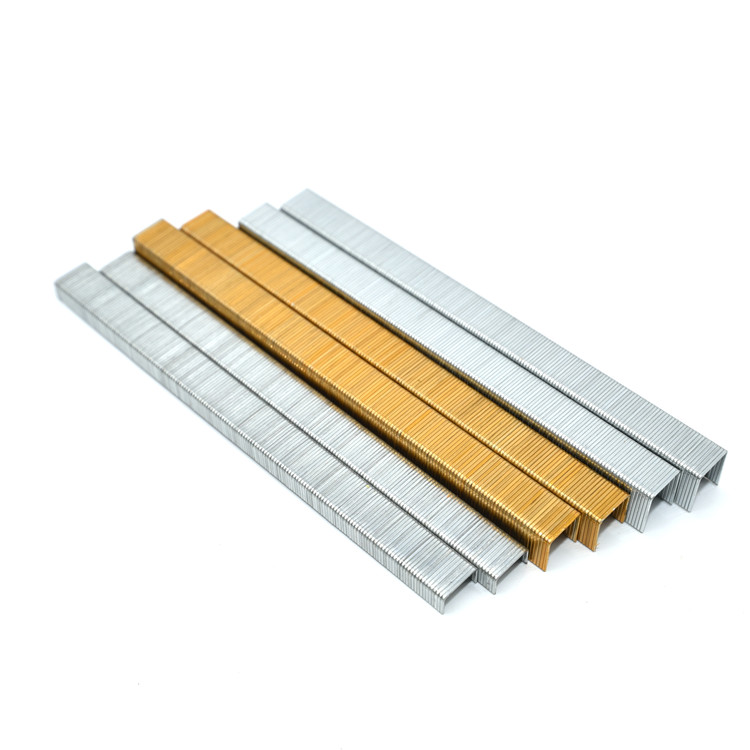

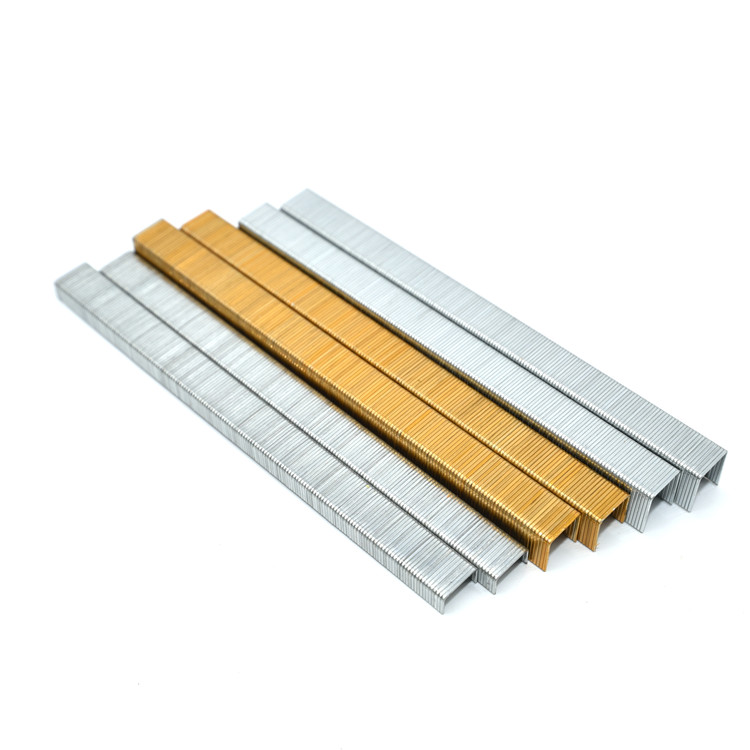

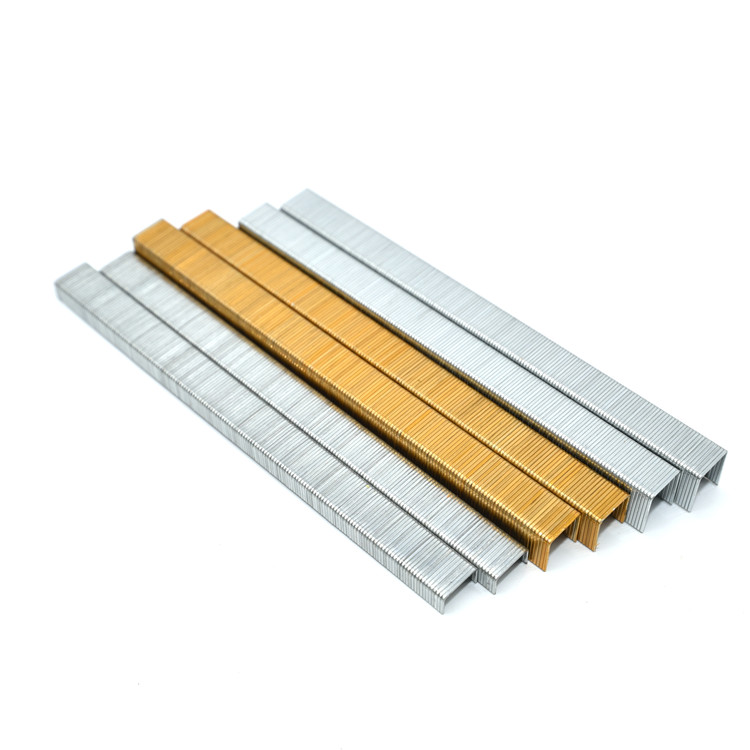

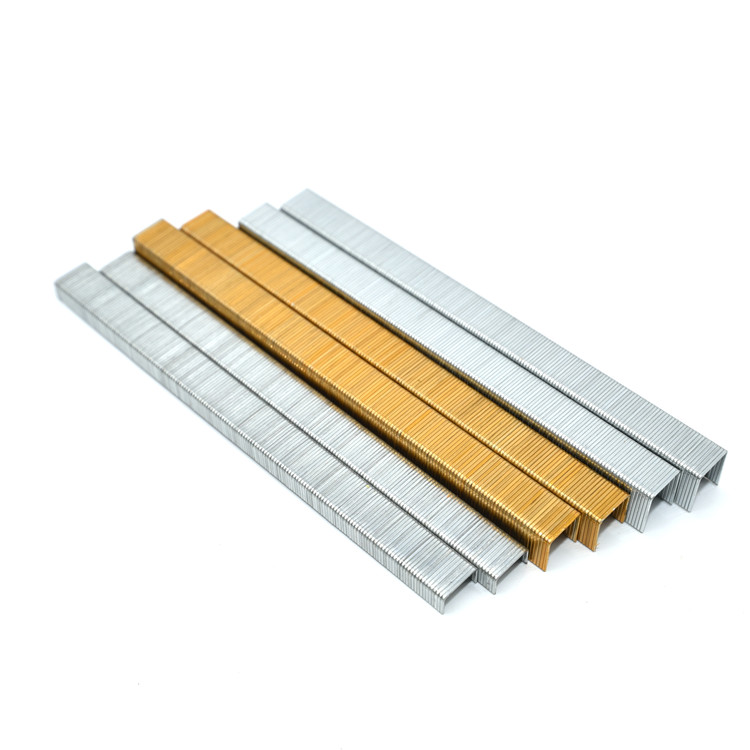

In the world of fasteners, galvanized brad nails stand out for their versatility and durability. As a manufacturer specializing in these essential tools, we understand the importance of producing high-quality nails that meet the diverse needs of contractors, DIY enthusiasts, and industry professionals alike. Our commitment to excellence begins with selecting the finest raw materials and employing cutting-edge manufacturing techniques to ensure each nail offers maximum strength and corrosion resistance.

The process starts with high-grade steel wire that undergoes rigorous testing to guarantee its quality before it enters our production line. Once approved, the wire is drawn through a series of dies to achieve the desired diameter and shape. This precision step is crucial as it sets the foundation for the nail's structural integrity.

Following this, the wire is fed into a machine that cuts it into specific lengths, creating the blanks that will soon become galvanized brad nails. These blanks are then headed, where a small piece of metal is flattened on one end to form the nail's head. The other end is pointed to a sharp tip, ready to penetrate any material with ease.

The real distinction comes with the galvanization process. We coat each nail with a layer of zinc through hot-dip galvanization. This not only shields the steel from rust and corrosion but also enhances the nail's ability to resist weather damage, extending its lifespan considerably This not only shields the steel from rust and corrosion but also enhances the nail's ability to resist weather damage, extending its lifespan considerably This not only shields the steel from rust and corrosion but also enhances the nail's ability to resist weather damage, extending its lifespan considerably This not only shields the steel from rust and corrosion but also enhances the nail's ability to resist weather damage, extending its lifespan considerably

This not only shields the steel from rust and corrosion but also enhances the nail's ability to resist weather damage, extending its lifespan considerably This not only shields the steel from rust and corrosion but also enhances the nail's ability to resist weather damage, extending its lifespan considerably galvanized brad nails manufacturer. The zinc coating acts as a sacrificial anode, protecting the steel underneath even when scratched or exposed to harsh environments.

Our state-of-the-art quality control measures ensure that every batch of nails meets our stringent standards. From the consistency of the zinc coating to the uniformity of the dimensions, we leave no stone unturned. This dedication to detail is why our galvanized brad nails are trusted by professionals who demand reliability and performance in their fastening solutions.

Moreover, we are acutely aware of the environmental impact of manufacturing processes. To mitigate this, we have implemented sustainable practices such as recycling excess zinc and reducing energy consumption throughout our plant. It's not just about making nails; it's about doing so responsibly.

In conclusion, as a manufacturer of galvanized brad nails, we pride ourselves on combining traditional craftsmanship with modern technology to deliver a product that stands the test of time. Our focus on quality, sustainability, and innovation ensures that our customers receive nothing short of the best. After all, a building is only as strong as the nails that hold it together, and we are committed to providing the strongest possible solution.

galvanized brad nails manufacturer. The zinc coating acts as a sacrificial anode, protecting the steel underneath even when scratched or exposed to harsh environments.

Our state-of-the-art quality control measures ensure that every batch of nails meets our stringent standards. From the consistency of the zinc coating to the uniformity of the dimensions, we leave no stone unturned. This dedication to detail is why our galvanized brad nails are trusted by professionals who demand reliability and performance in their fastening solutions.

Moreover, we are acutely aware of the environmental impact of manufacturing processes. To mitigate this, we have implemented sustainable practices such as recycling excess zinc and reducing energy consumption throughout our plant. It's not just about making nails; it's about doing so responsibly.

In conclusion, as a manufacturer of galvanized brad nails, we pride ourselves on combining traditional craftsmanship with modern technology to deliver a product that stands the test of time. Our focus on quality, sustainability, and innovation ensures that our customers receive nothing short of the best. After all, a building is only as strong as the nails that hold it together, and we are committed to providing the strongest possible solution.

This not only shields the steel from rust and corrosion but also enhances the nail's ability to resist weather damage, extending its lifespan considerably This not only shields the steel from rust and corrosion but also enhances the nail's ability to resist weather damage, extending its lifespan considerably

This not only shields the steel from rust and corrosion but also enhances the nail's ability to resist weather damage, extending its lifespan considerably This not only shields the steel from rust and corrosion but also enhances the nail's ability to resist weather damage, extending its lifespan considerably galvanized brad nails manufacturer. The zinc coating acts as a sacrificial anode, protecting the steel underneath even when scratched or exposed to harsh environments.

Our state-of-the-art quality control measures ensure that every batch of nails meets our stringent standards. From the consistency of the zinc coating to the uniformity of the dimensions, we leave no stone unturned. This dedication to detail is why our galvanized brad nails are trusted by professionals who demand reliability and performance in their fastening solutions.

Moreover, we are acutely aware of the environmental impact of manufacturing processes. To mitigate this, we have implemented sustainable practices such as recycling excess zinc and reducing energy consumption throughout our plant. It's not just about making nails; it's about doing so responsibly.

In conclusion, as a manufacturer of galvanized brad nails, we pride ourselves on combining traditional craftsmanship with modern technology to deliver a product that stands the test of time. Our focus on quality, sustainability, and innovation ensures that our customers receive nothing short of the best. After all, a building is only as strong as the nails that hold it together, and we are committed to providing the strongest possible solution.

galvanized brad nails manufacturer. The zinc coating acts as a sacrificial anode, protecting the steel underneath even when scratched or exposed to harsh environments.

Our state-of-the-art quality control measures ensure that every batch of nails meets our stringent standards. From the consistency of the zinc coating to the uniformity of the dimensions, we leave no stone unturned. This dedication to detail is why our galvanized brad nails are trusted by professionals who demand reliability and performance in their fastening solutions.

Moreover, we are acutely aware of the environmental impact of manufacturing processes. To mitigate this, we have implemented sustainable practices such as recycling excess zinc and reducing energy consumption throughout our plant. It's not just about making nails; it's about doing so responsibly.

In conclusion, as a manufacturer of galvanized brad nails, we pride ourselves on combining traditional craftsmanship with modern technology to deliver a product that stands the test of time. Our focus on quality, sustainability, and innovation ensures that our customers receive nothing short of the best. After all, a building is only as strong as the nails that hold it together, and we are committed to providing the strongest possible solution. Latest news

-

Manufacturer producing brad nails for staple guns with high quality and durability.NewsJul.16,2024

-

CE certification for 5-8mm brad nails and its importance in construction.NewsJul.16,2024

-

Top 16 Gauge Brad Nail Manufacturers with High Quality Products and ServicesNewsJul.16,2024

-

China 18 Gauge Brad Nails for Precision Carpentry Projects in 2021.NewsJul.16,2024

-

Top manufacturer of BN1810 brad nails, providing high quality products for various applications.NewsJul.16,2024

-

Get the job done with 18-gauge staples in 40mm size for various projects.NewsJul.15,2024