Jul . 12, 2024 11:05

Back to list

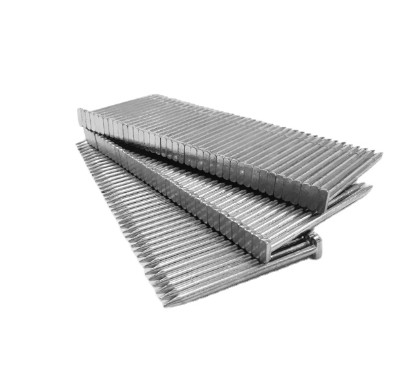

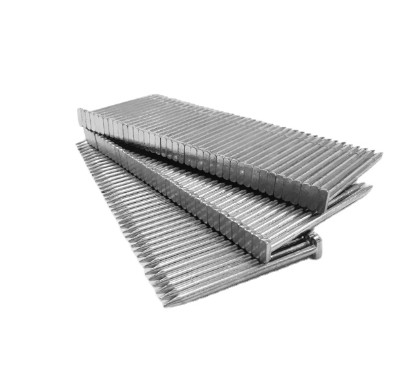

Manufacturer of staples for underlay products offers quality and reliable solutions for flooring.

Staples for Underlay Manufacturer

Staples play a crucial role in the production of underlay, a material that is used in flooring applications to provide padding, insulation, and soundproofing. As a manufacturer of underlay, it is important to source high-quality staples to ensure the integrity and longevity of the product.

One of the key considerations when selecting staples for underlay production is the material composition. Staples are typically made from metals such as steel, stainless steel, or brass. Steel staples are durable and cost-effective, making them a popular choice for underlay manufacturing. Stainless steel staples are resistant to corrosion and rust, making them ideal for environments with high moisture levels. Brass staples are also a good option for underlay production due to their strength and corrosion resistance.

In addition to material composition, the size and shape of the staples are important factors to consider. The size of the staple should be compatible with the thickness of the underlay material to ensure a secure and long-lasting bond. The shape of the staple, whether it is flat, chisel-point, or divergent, can also impact the performance of the underlay. Flat staples provide a larger surface area for gripping the underlay, while chisel-point staples penetrate the material more easily

staples for underlay manufacturer. Divergent staples have legs that bend outwards upon penetration, creating a strong hold. When selecting staples for underlay manufacturing, it is important to consider the type of underlay being produced. For example, underlay for carpeting may require different staples compared to underlay for hardwood flooring. Carpet underlay typically requires staples with a sharp point to penetrate through the carpet backing, while hardwood flooring underlay may require flat staples to prevent damage to the flooring surface. Another important consideration when sourcing staples for underlay production is the installation method. Staples can be applied using manual or pneumatic staple guns, depending on the volume and type of underlay being produced. Pneumatic staple guns are often used in high-volume manufacturing settings to increase efficiency and productivity. In conclusion, staples play a critical role in the manufacturing of underlay for flooring applications. When selecting staples for underlay production, factors such as material composition, size, shape, and installation method should be carefully considered to ensure the quality and performance of the final product. By partnering with a reputable staple supplier, underlay manufacturers can source high-quality staples that meet their specific requirements and contribute to the overall success of their business.

staples for underlay manufacturer. Divergent staples have legs that bend outwards upon penetration, creating a strong hold. When selecting staples for underlay manufacturing, it is important to consider the type of underlay being produced. For example, underlay for carpeting may require different staples compared to underlay for hardwood flooring. Carpet underlay typically requires staples with a sharp point to penetrate through the carpet backing, while hardwood flooring underlay may require flat staples to prevent damage to the flooring surface. Another important consideration when sourcing staples for underlay production is the installation method. Staples can be applied using manual or pneumatic staple guns, depending on the volume and type of underlay being produced. Pneumatic staple guns are often used in high-volume manufacturing settings to increase efficiency and productivity. In conclusion, staples play a critical role in the manufacturing of underlay for flooring applications. When selecting staples for underlay production, factors such as material composition, size, shape, and installation method should be carefully considered to ensure the quality and performance of the final product. By partnering with a reputable staple supplier, underlay manufacturers can source high-quality staples that meet their specific requirements and contribute to the overall success of their business.

Latest news

-

Manufacturer producing brad nails for staple guns with high quality and durability.NewsJul.16,2024

-

CE certification for 5-8mm brad nails and its importance in construction.NewsJul.16,2024

-

Top 16 Gauge Brad Nail Manufacturers with High Quality Products and ServicesNewsJul.16,2024

-

China 18 Gauge Brad Nails for Precision Carpentry Projects in 2021.NewsJul.16,2024

-

Top manufacturer of BN1810 brad nails, providing high quality products for various applications.NewsJul.16,2024

-

Get the job done with 18-gauge staples in 40mm size for various projects.NewsJul.15,2024